HOW TO POLISH ACRYLIC: DIY GUIDE

The Plastic Warehouse Guide To Polishing Acrylic

Acrylic/Perspex/Plexiglas sheets are probably the most common plastic sheet being used in DIY applications. This isn’t a surprise considering the huge number of uses for this product, as well as it being relatively easy to work with and install.

One often overlooked aspect of working with acrylic is polishing. You may be surprised to read this, but polishing the edges of an acrylic panel is easier to do at home than you might think.

Sanding and polishing the edges of your acrylic panel is recommended for achieving the best appearance, particularly after cutting it to size. This will smooth rough edges, remove scratches and leave a glossy appearance.

The following guide should help with the right materials and methods to follow, however, this is intended as a guide only. We also recommend that you test this first on an offcut or inconspicuous area first, to determine if this is suitable and achieves the desired result..

Materials and tools for polishing acrylic sheet edges

Various methods are available for polishing acrylic sheet, but some of these are not suited to DIY users.

- By hand with paste and cotton cloth – Great for DIY or at home projects

- Cloth buffing wheel and wax – Great for DIY or at home projects

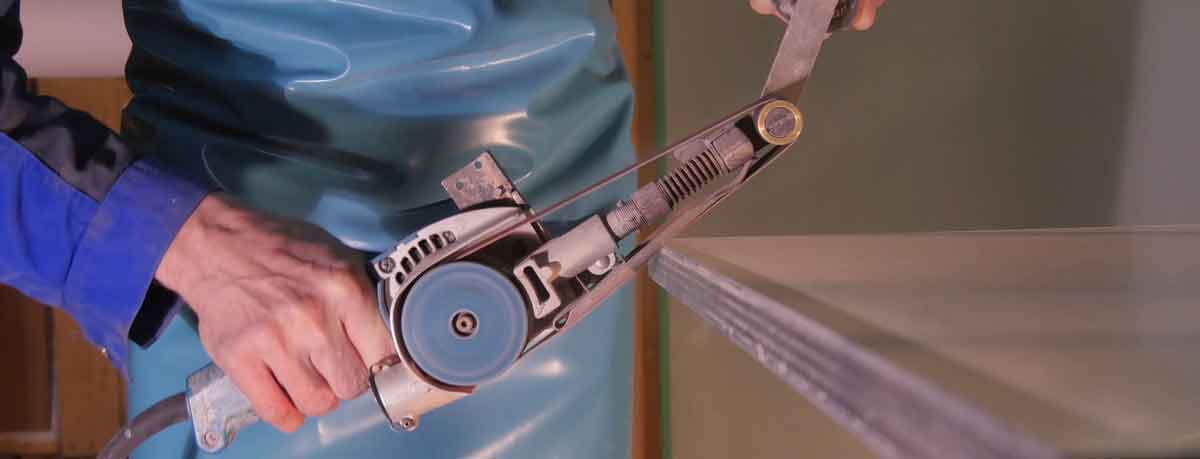

- Flame polishing – Experience and special tools needed

- Diamond polishing – Experience and special tools needed

Polishing by hand is pretty straight forward. Just be sure to select a polishing paste or compound that has been specifically designed for plastic and follow the manufacturers instructions.

SANDING AND POLISHING ACRYLIC SHEET

Materials and tools for sanding and polishing acrylic sheet

- Sanding block

- Wet sanding paper

- Cotton cloth

- Polishing paste

- Water

- Cloth buffing wheel with polishing wax (optional)

How to smooth and polish acrylic sheet edges by hand

- Secure your acrylic sheet using clamps or a vice with protective jaws. Ensure there are no sharp edges or anything that could scratch or damage the surface of your plastic sheet when secured in place.

- Smooth your edges out with a scraper (if needed). Use a moderate pressure, gliding the scraper along the cut edge several times until marks and scratches are removed.

- Wrap the sandpaper around a wooden or cork block to grind the cut edges.

- Sand your edges with wet sanding paper. We recommend starting with a course sandpaper and repeating the process with finer grits. The choice of abrasive grit depends on the depth of the marks or scratches you are trying to remove: The deeper these marks, the coarser the grit. Finish with a very fine (1000 grit) paper. Always use water when sanding to avoid thermal stress on the plastic and to stop the paper clogging.

- Clean off any excess plastic from sanding with a damp cloth.

- Apply a polishing compound or paste using a cotton cloth, following the manufacturers instructions.

How to polish acrylic sheet with a cloth buffing wheel

- Secure your acrylic sheet using clamps or a vice with protective jaws. Ensure there are no sharp edges anything that could scratch or damage the surface of your plastic sheet when secured in place.

- Remove dirt and other contaminants from materials and tools before you start buffing to avoid damaging the acrylic.

- Clamp the cloth buffing wheel in the drill. Large and curved surfaces are easily polished with a cloth buffing wheel clamped in a commercially available drill.

- Apply polishing wax. Make sure that the cloth buffing wheel is free from old wax. Apply the new polishing wax on the rotating disc.

- Set the Speed. With the drill power on, set the rotational speed based on the size of the buffing wheel. If this has a large diameter, set a low rotational speed; if the diameter is small, a high rotational speed is recommended. Please also refer to the manufacturer’s instructions where relevant.

- Polish. Move the cloth buffing wheel across the surface of your acrylic with a light and even pressure. Do not press down with the polishing tool at any one spot of the material too long or with too much force. It is best to let the tool do the work for you.

- Remove polishing wax. At the end of the process, remove excess wax with a dry cloth.

Please note, our technical advice on the use of our materials is given without obligation. The buyer is responsible for the application and processing of our products. Technical data concerning our products are typical values. Subject to alteration.

Australia’s Best Range Of Acrylic Sheets At Your Fingertips

Here at Plastic Warehouse, we offer the largest range of acrylic products direct to the public.

You can order standard size sheets and custom “Cut to Size” panels directly from our product pages. On the desired product page simply select “Cut to Size” from the drop down option.

You can view our range of acrylic sheets here.

If you have any queries or need further information on our acrylic sheet range, please check out our FAQ’s page here or drop us an email here.